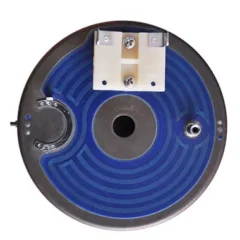

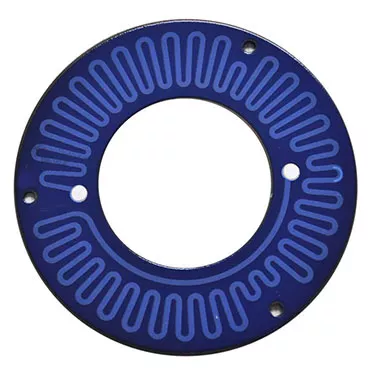

Thick film heaters are ideal for applications which require uniform heating and fast response. The integration of heating circuits with heat sinks leads to excellent heat transfer. Compared to ordinary tubular heating element, thick film heaters have large surface for heat transfer while taking less space.

The substrate for thick film heaters can be stainless steel, ceramic or even glass. The shape can be flat or curved planes or tubes. For low temperature high resistance application we have thin film heater solution making use of partical sputtering.

Thick film heaters can be installed by application of holes, screws, nuts, welds, spring contact.

Technical Specification

| Input volatge | 0 – 240V | Max Temperature | 550°C (note 1) | Min width | 57mm |

| Watt density | ≤ 12 W/cm2 | Min Temperature | – | Max width | 610mm |

| Wattage | up to several KW (note 2) | Watt tolerance | ≤ ±5% (±2% possible) |

Notes:

- Ceramic based thick film heaters have higher temperature rating due to the similar expansion rate.

- Thick film heaters feature a significant PTC effect. Their power decreases consecutively with rising of temperature.

Applications

In connection with the intrinsic structural advantages, thick film heaters are widely used for:

- AC line voltage heater: radiators, heating panels, flow through heaters;

- Discharging power resistors;

- Food & beverage dispenser, white goods;

- Automotive: thermal management for electric vehicle battery, cabin and comfort heating;

- Semiconductor: wafer processing;

- Packing and sealing equipment;

- Analytical devices, e.g. DNA analyzer